Product description

Efficient usage of waste heat increases economic efficiency. The savings generated by process heat recovery can be high.

Heat recovery makes use of energy that would otherwise be wasted by reintroducing it back into the process. One example of this is controlled ventilation in which the heat of the waste extracted air is used to bring the fresh, cold outside air up to a comfortable temperature without having to use a heating system. This not only saves on heating costs, it is also environmentally friendly.

The aim of heat recovery is to minimise the primary energy demand. This meets both energy efficiency and environmental requirements. In the simplest scenario, with relatively continuous heat dissipation and absorption, a heat exchanger is sufficient. If this is not the case, an additional heat storage tank is required.

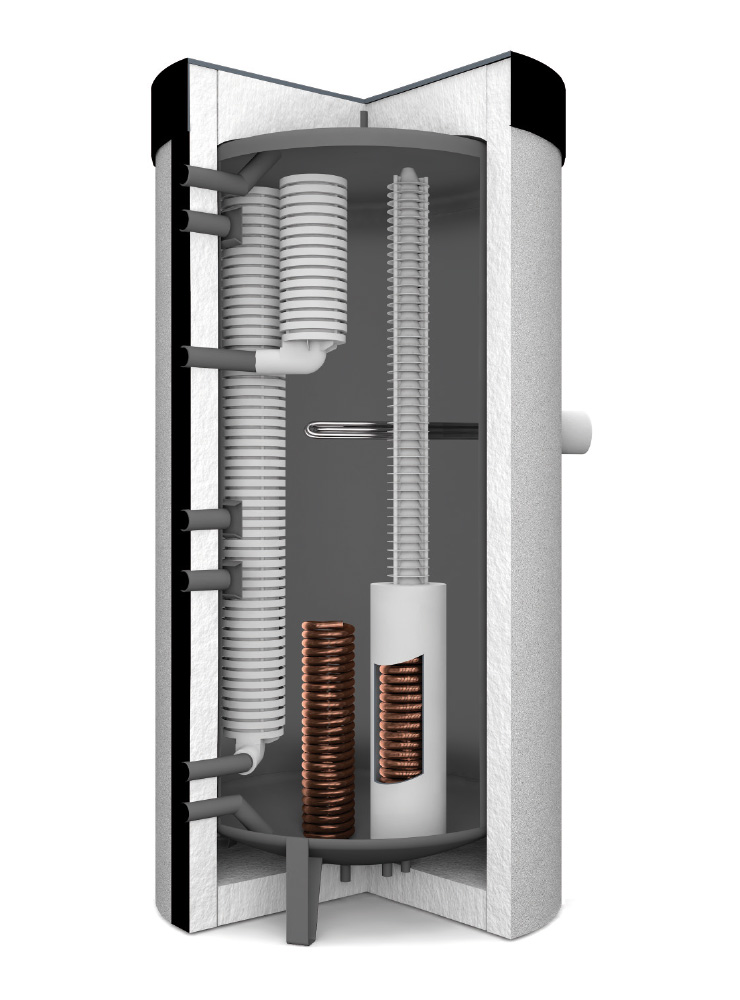

Sailer supplies a suitable stratified storage tank with stageless input stratification.

Downloads

Hydraulic diagrams

List of diagrams

1.0_Symbols

List of diagrams 1.0_Symbols 13.B FRIWASTA Plus, system separation, heat recovery tank and heat source

Accessories

Insulation for Sailer storage tanks

Insulation for Sailer heat and cold storage tanks, and for large and special storage tanks

Cold and heat storage up to 100.000 Liters

More Info

![[Translate to Englisch:] Large and special storage tanks](/fileadmin/dateien/bilder_speicher/bild_sonderspeicher.jpg)

![[Translate to Englisch:] Oval storage tanks](/fileadmin/dateien/bilder_speicher/bild_ovalspeicher.jpg)