Polyester fleece, mineral wool, AF/Armaflex, multi-layer system for combined cold and heat layer storage

Product description

All-Round Protection against loss of Heat or Cold

THE COMPLETE PACKAGE FOR ENERGY EFFICIENCY

Sailer was looking for ways to minimise energy losses, increase energy efficiency and save resources even before the introduction of the energy label and ecodesign requirements. Sailer offers the following heat/cold insulation as standard:

- Polyester fleece in a resistant polystyrene jacket

- Mineral fibre for large tanks with sheet metal cladding

- AF/Armaflex insulation for cold storage tanks

ECODESIGN DIRECTIVE FOR STORAGE TANKS

Since 26 September 2015, the Ecodesign Directive has also stipulated requirements for heat exchangers. Package labels for composite systems are based on the tank capacity and the standing loss. Sailer's stratified charging technology optimises the energy efficiency of storage tanks and the complete system to exceed the requirements of the Ecodesign Directive.

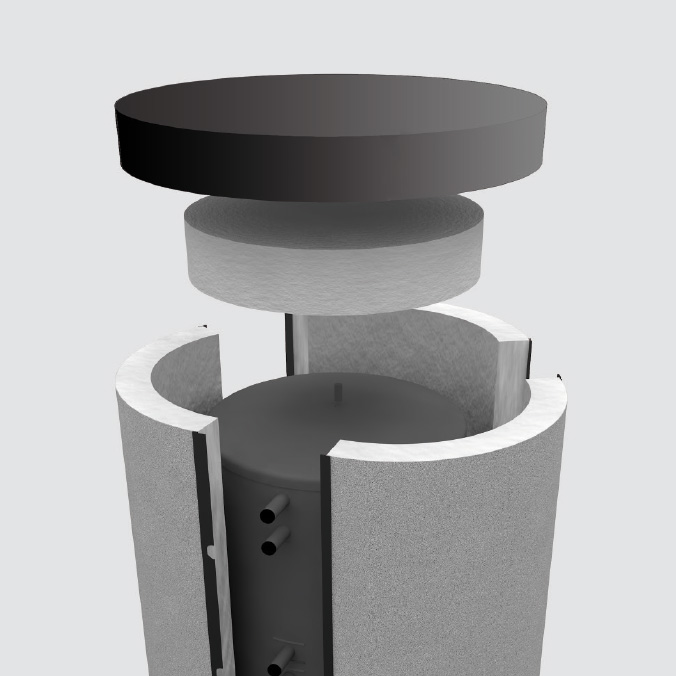

Polyester fleece 100-160 mm – thermal insulation with ErP class C and B.

Our non-recycled polyester fleece with polystyrene jacket is produced in certified manufacturing plants and provides the best insulating properties.

You can choose between two types of insulation as defined in the Ecodesign Directive and the ErP Directive: ErP Class C Standard with a thickness of 100-110 mm and ErP Class B, which saves up to 30% energy and has a thickness of 130-160 mm. The tanks are also supplied with a cover insulation that is 160 mm thick.

The multi-part thermal insulation with the resistant polystyrene jacket can be installed after the pipework has been installed. The multi-part insulation kit has fasteners on all sides, making installation easy. These are concealed by an end strip. This avoids damage and dirt that can be caused during construction work. The thermal insulation is designed to complement the shape of the tank, while the polystyrene jacket ensures it remains in place.

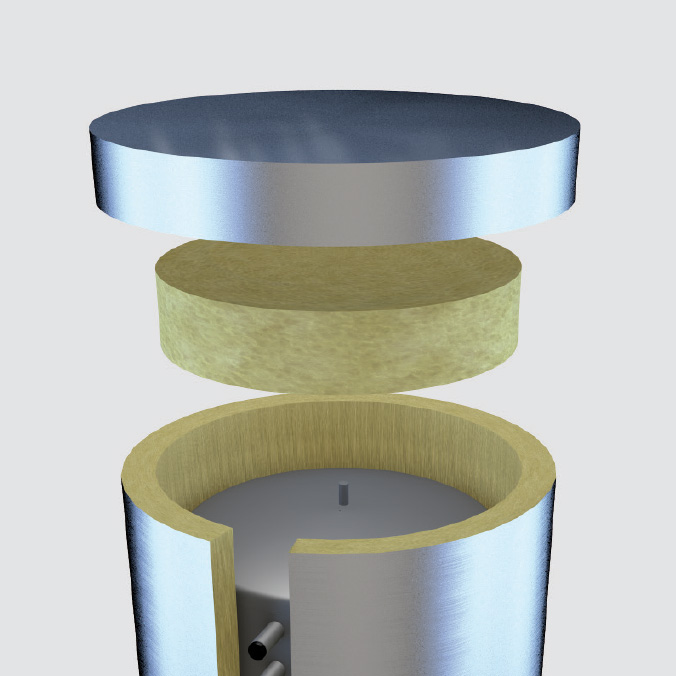

Mineral fibre 100-400 mm – ideal for insulating large tanks!

Mineral fibre (rock wool) is a synthetic mineral insulation material that provides an outstanding thermal insulation solution for special and large tanks, sufficiently protecting them against thermal losses. Mineral fibre is breathable and resistant to mould, rot and vermin. It can absorb moisture and has good fire resistance properties. Insulation for special and large tanks up to 400 mm is supplied as a sheet metal jacket.

AF/Armaflex 19-50 mm – insulation with condensation protection!

Armaflex is an insulation with very low thermal conductivity. It guarantees long-term energy efficiency, prevents condensation and permanently prevents energy losses.

The optimal combination of the exceptionally low thermal conductivity and a high water vapour diffusion resistance helps reduce the penetration of water vapour and reduces the risk of corrosion under the insulation. Thanks to the integrated antimicrobial Microban® protection and the outstanding fire behaviour, Armaflex is particularly suitable for use in public buildings and process plants.

We offer two design variants:

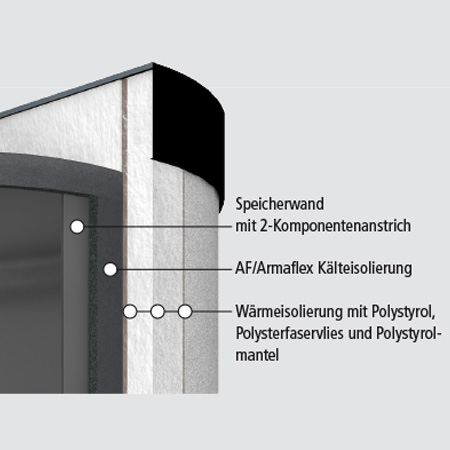

Variant 1: The storage tank is given a two-component coating. The Armaflex insulation is supplied cut to size in the box.

Variant 2: The storage tank is given a two-component coating, is insulated with Armaflex in the factory and also has an additional sheet metal jacket.

The advantages at a glance:

- Stable thermal conductivity for long-term energy efficiency

- Integrated antimicrobial protection with Microban®

- Integrated water vapour barrier reduces the risk of corrosion under the insulation

- Euroclass B/BL-s3,d0 approved

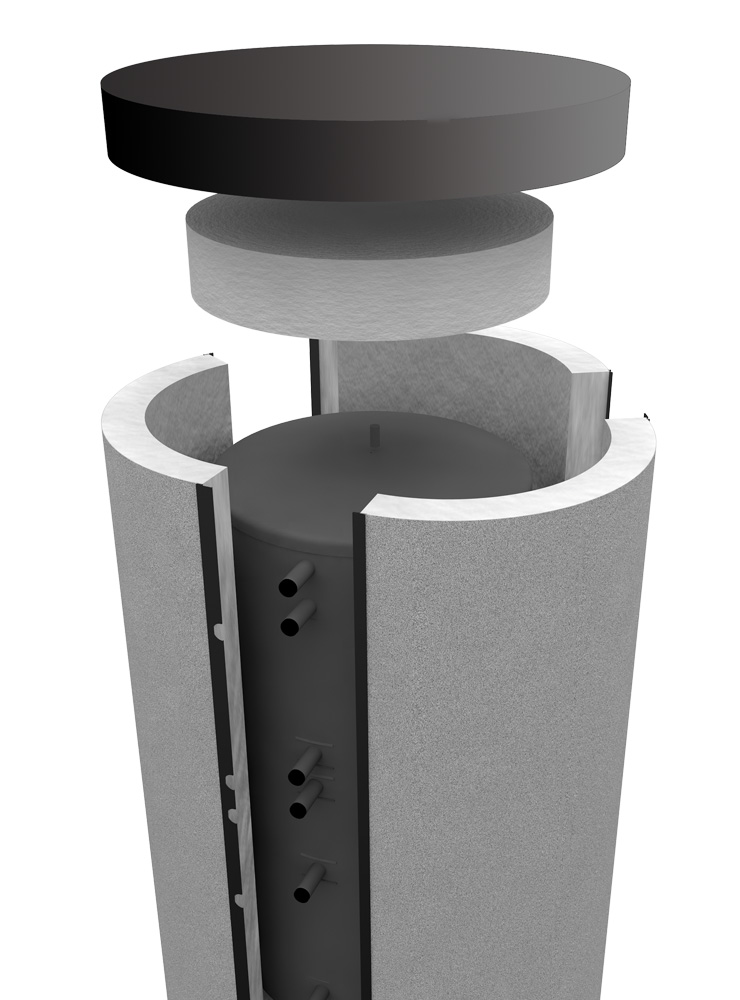

Optimised multi-layered system for combined stratified cold and heat storage tanks

Sailer supplies an optimised multi-layered system for all combined cold/heat storage tanks.

First, the outer wall of the storage tank is covered with a two-component coating. This protects the storage tank against corrosion and is solvent-resistant. Then an AF/Armaflex cold insulation mat with high water vapour diffusion resistance and very low thermal conductivity is glued on. This is followed by a triple-layered, 80-mm thermal insulation system:

Layer 1 is expanded polystyrene

Layer 2 is a layer of polyester fleece

Layer 3 (cover layer) is an impact-resistant polystyrene jacket

Cold and heat storage up to 100.000 Liters

More Info